|

|||||||||||||||||||||||||||||||||||||||||

| Products & Pricing > Wood Boards > Process (Redwood) | |||||||||||||||||||||||||||||||||||||||||

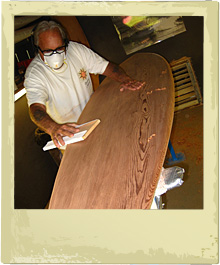

| Here's how Johnny hand-crafts wood boards. You can see the end result is one bitchin' board... Whether it's wood, foam or epoxy boards, every step in the process has his fullest attention to detail. Quality craftsmanship thru 'n' thru. (You can click each image to enlarge.) | |||||||||||||||||||||||||||||||||||||||||

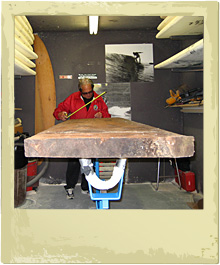

| Johnny at Work |

Examining the redwood plank that Johnny had cured out at his shop for 18 years. |

Putting the measurements on before laying down the template. |

|||||||||||||||||||||||||||||||||||||||

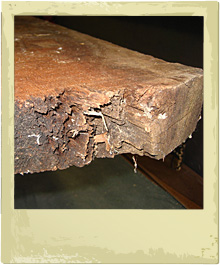

This is one of the ends of the solid plank of redwood. |

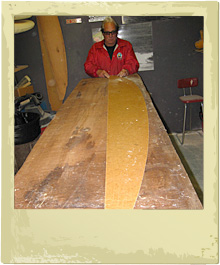

Putting on the template. This is the beginning of what the shape will be. |

Johnny is cutting out the shape with the power sawzall. |

|||||||||||||||||||||||||||||||||||||||

The left over redwood pieces. |

Working on the nose and giving the board its shape according to the original measurements. |

Johnny is sanding the board down. This takes many many hours to do to make it perfectly symetrical. |

|||||||||||||||||||||||||||||||||||||||

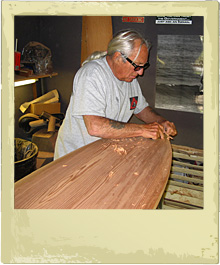

Gluing the tail block. Johnny makes all his own tail blocks. |

The tail block has been glued on to the redwood board after it has been shaped. |

This is the board ready to go to the glass shop. You will notice the "V" shape bottom that is created. That is because in the days of the past when fins were not used there was a V-shape so one can turn the board. |

|||||||||||||||||||||||||||||||||||||||

The board in the glass shop. |

This is where the board is being sanded in the glass shop. |

The finished board showing the tail block and his logo with Johnny's signature. |

|||||||||||||||||||||||||||||||||||||||

Marty with Johnny standing with his redwood board. |

|||||||||||||||||||||||||||||||||||||||||

| Back to top | |||||||||||||||||||||||||||||||||||||||||

|

Johnny Rice Hand-Shaped Custom Surfboards Longboards Santa Cruz California | Tel: 831-423-0175 |

|||||||||||||||||||||||||||||||||||||||||